R. Dr. Francisco Sá Carneiro

Zona Industrial de Bouro - Letra C

4740-010 Esposende, Portugal

Industrial Glass Protect

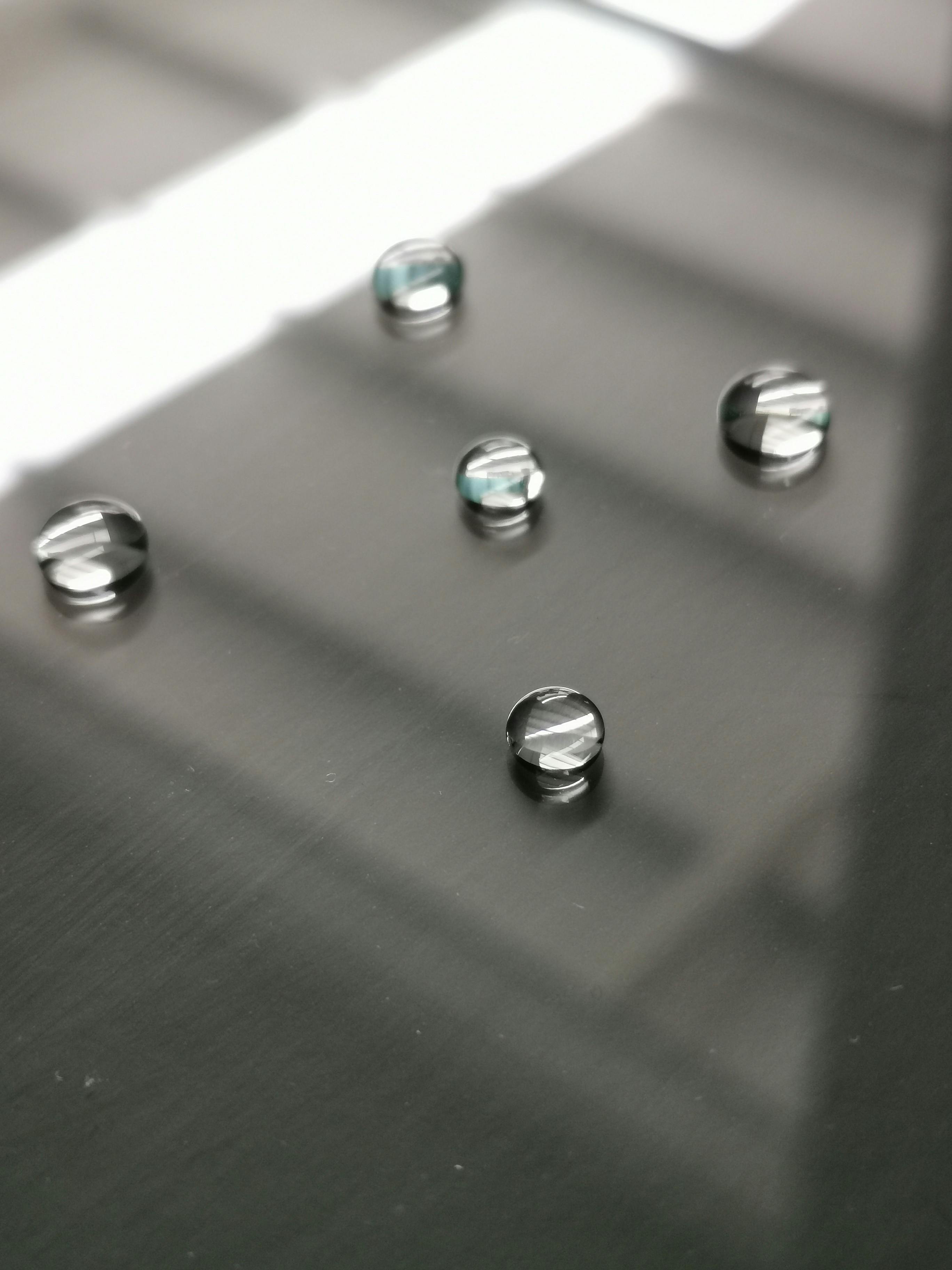

Glass coating easy-to-apply – A premium DIY surface coating with hydrophobic (water repellent) and oleophobic (oil repellent) properties, developed and optimized to create an invisible shield to the glass that will prevent its deterioration and minimize the adherence of dirt and grease/oil, facilitating the cleaning process.

Each kits includes:

- 1x Pre-Cleaner for a previous cleaning of the surface (125 mL);

- 1x IGP coating to protect your glass (50 mL);

- 2x Premium Microfiber Cloths - one to clean the surface and the other to polish it after applying the coating;

- 1x Steel Wool Roll to remove those pesky limestone stains from your glass before applying the coating;

- 1x Instructions Manual and FAQs

Protect your glass at home. Reduce cleaning time by up to 90% and enjoy your free time doing what you really want!

Benefits

- Cuts cleaning time by more than 90%

- Keeps the surfaces clean for longer

- Protection against hard water stains and other residues (shampoo, soap, etc.)

- Long lasting – 3 years of limited warranty

- Protects against saline environments

- Protects against cement slurry

- Protection against graffiti – reduced adhesion of the paint

- Certified UV and abrasion resistance

Features

- Faster and easier cleaning, which allows the reduced use of consumables

- Ready to use and easier to apply – can be applied without any expensive proprietary machinery

- Suitable for application on other non-porous surfaces as aluminum frames, stainless steel, painted surfaces, etc.

- Short curing time even at room temperature

- Environmentally friendly (Non-Toxic & Biodegradable)

- Free from fluorocarbons and other chemicals that negatively affect the environment

Suitable for all types of glass

Surface treatment for easy to clean glass and other non-porous materials - CUTS CLEANING TIME BY MORE THAN 90%

How it works? Protects against limestone build-up, grease and dirt in general. Glass stays cleaner for longer.

Applications

Where to use

Mirrors

Windows

Towel racks

Taps

Skylights

Shower cubicles and enclosures

Swimming pool covers and Balconies

How to apply?

Apply the pre-cleaner in small sections - between 0.5 to 1m2.

Use the yellow microfiber cloth - provided in the kit - to clean the glass surface.

If the glass still has lime scale stains and/or any visible encrusted dirt in the area previously sprayed, follow step 4. If the glass is already clean, you should proceed to step 5.

Use the steel wool roll to help remove encrusted dirt. Clean the area again with the pre-cleaner to remove any residue from the steel wool and dirt.

Apply a fine mist of IGP over the desired section, spraying the coating between 10 to 20 cm. Repeat the process until the entire surface is coated with IGP.

Use the blue microfiber cloth - provided in the kit - to polish the entire surface until the product is completely absorbed and the glass is free of any stains.

When all glass is treated with the PGI, allow the product to cure for 1.5 to 2 hours before putting the glass back in contact with water or any type of chemicals (detergents, shampoo, soap, etc.)

After the curing time, your surface is now protected with the hydrophobic coating! The surface protected with PGI should be cleaned with a microfiber cloth and, if necessary, with a mild pH, non-abrasive, neutral detergent such as our pre-cleaner.

Warranty

ChemiTek guarantees that the IGP - Industrial Glass Protect coating will resist all types of water or oil-based soiling for a period of 3 years from the date of application of the product. The warranty is only valid if the application occurs before the expiration date of the product and if all the instructions and indications given in this document are followed.

If the IGP does not remain water repellent during the warranty period, ChemiTek will replace the amount of product required for reapplication to the area in question.

Tüv Certification

The product tests made by the TÜV Sud laboratory proved that the Industrial Glass Protect:

- Light transmission – increased by 2,8% (acc. to EN 60068)

- Surface abrasion test – no abrasion was visible

- Microscopic examination of the surface – no scratch was visible

- Cleaning efficiency – improved

FAQ List

The IGP Kit includes: 1 sprayer of 125 mL of pre-cleaner for cleaning the glass/surface before applying the coating; 1 yellow microfiber cloth to clean the entire surface after applying the pre-cleaner; 1 sprayer of 50 mL of IGP hydrophobic coating; 1 blue microfiber cloth to polish the entire surface after applying the coating on the glass/surface; 1 steel wool roll to remove those pesky limestone stains that aren't coming off easily with the pre-cleaner only; Instructions and FAQs.

IGP can be applied to all types of glass, such as tempered, laminated, thermal, textured, tinted, acid etched, sandblasted, and curved glass, and in all types of applications such as shower enclosures, mirrors, windows, glass doors, solar panels, skylights, or pool screens.

Yes, IGP can be applied on all kinds of chrome or stainless steel fittings, such as taps, tower rails, handles, etc., with identical results to those obtained in the glass.

After opening the package, we recommend using it in the following 12 months.

Yes, IGP has hydrophobic (water repellent) and oleophobic (oil repellent) properties that make the glass easier to clean.

No, the wear of the coat doesn’t cause stains and is not visually noticeable. To confirm that your glass is still protected, check if the water repellence effect is still present.

Proper glass preparation is essential for good adhesion of the coating to the glass. The glass must be free of dirt, grease and lime scale incrustations, soap and or shampoo.

Yes, new glass also must be prepared. Since there are no incrustations present, the glass only needs to be cleaned and degreased.

Yes, on glass that already shows degradation it may no longer be possible to remove all stains and/or scratches. The presence of the coating will prevent further degradation of the glass and make it easier to clean.

No, the coating will not stain or damage materials such as plastic, silicone, aluminium, or wood. If the coating meets any of these materials during application, simply wipe the surface clean until the product is no longer visible. Temporary water repellence may occur on that same surface.

The recommended quantity is 5 to 10mL per square meter. A fine mist over the entire surface is sufficient. The product should not be enough to run off.

In case of over-application of the product, the solution is simple. The glass will look greasy, and it will be necessary to remove the excess product with a microfiber cloth. After removing the excess, use a clean microfiber cloth to polish the surface until the product is no longer visible.

The ideal temperature to apply the product is between 15ºC and 30ºC, and low to medium relative humidity. These two factors are particularly important when applying the product on exterior glass. Low temperature will delay the curing of the coating and high temperatures lead to accelerated evaporation of the product during application.

The recommended curing time is 1,5 to 2 hours. During this time the glass should not have contact with water neither with any chemicals such as soap, shampoo and/or conditioner.

If it rains during the curing period, the coating will not be affected, and as such it does not need to be reapplied.

When you notice that the coating has reached the end of its life and is no longer performing as expected, you can reapply the IGP. Simply repeat the application process as you did the first time. It is not necessary to remove the previous coating before reapplying IGP.

Yes. The IGP coating helps keeping the glass cleaner for longer by making it harder for dirt to build up on the surface. However, it does not eliminate the need for cleaning, as it is not a self-cleaning product.

The correct application of the coating guarantees a lifespan of more than 3 years.

Glass protected with IGP should be cleaned with a microfiber cloth and, if necessary, a mild, non-abrasive, neutral pH detergent. NEVER use abrasive and/or highly acidic or alkaline detergents, as it will greatly shorten the life of the coating. If your area has hard water and causes a lot of limescale deposits, we suggest using pure white vinegar diluted in water in a 1 to 5 ratio (200mL of vinegar for every litre of water) to clean the glass.

The wear caused by normal cleaning of the glass with a microfiber cloth is extremely low. The main reasons for accelerated wear of the coating are the use of aggressive and/or abrasive detergents and the use of scouring pads and other abrasive tools for cleaning the glass.

If your glass is still easy to clean and the water repellent effect is still there, then your glass is still protected.