R. Dr. Francisco Sá Carneiro

Zona Industrial de Bouro - Letra C

4740-010 Esposende, Portugal

Solar Glass

The glass used in the manufacture of the solar panel is not ordinary glass. It is a special ultra-pure glass with low iron content, specially developed to reflect less and let the maximum light pass through it. Usually, the glass used in photovoltaic solar panels is tempered glass.

The solar panel glass is one of the most important barriers protecting the photovoltaic solar cells from harmful external factors such as water, steam, dust, or dirt. This is a very important part of the photovoltaic system because it will make a difference in the efficiency of the solar panel, and therefore in the performance of the photovoltaic solar system.

What is tempered glass?

Tempered glass is also referred to as safety glass or toughened glass and it’s 6 times more resistant of normal glass. It is manufactured by thermal or chemical means to increase its strength. Tempering puts the outer surface into compression and the interior into tension.

There are specific properties that make this type of glass the most suitable for the manufacture of solar panels. It is much stronger than other types of glass, such as standard flat glass, and it is still considered safety glass. When it breaks, it will shatter into thousands of small pieces, that won’t be harmful since the granular chunks are less likely to cause injury.

The solar glass must ensure low reflectivity, high light transmission, and high strength

• Low reflectivity: obtained with the anti-reflectivity coating

• High light transmission: maximum transparency

• High resistance: tempered glass 3 to 4mm thick

Panels with good quality glass will resist even the heaviest hailstorms. This special glass represents approximately 10% of the solar panel manufacturing cost.

The Anti-Reflective Coating

The main purpose of the solar panel glass is to transmit as much sunlight as possible to the module. Highly transmissive glass has a direct positive effect on the performance and yield of solar panels. Maximum transparency leads to high light transmission.

The low reflectivity is obtained through the coating present on the glass, anti-reflectivity effect – AR Coating.

The anti-reflective coating can be added to solar panel glass by coating it with a layer of anti-reflective film before the glass is tempered. This additional anti-reflective coating on the solar panel glass reduces the amount of reflected light and thus increases the percentage of sunlight absorbed by the photovoltaic solar. A silicon cell will reflect 30% of the light received. When coated with AR Coating, the light reflected will drop to around 10%.

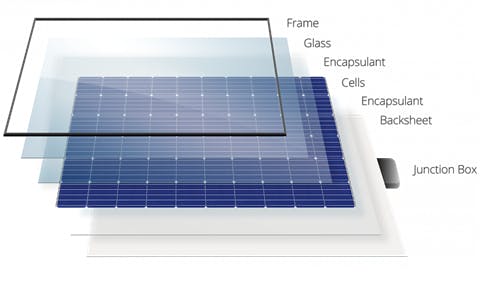

The backsheet

Crystalline solar panels are composed of a rough surface, this surface is necessary for the EVA film to adhere well to the glass of the solar panel during the lamination process. EVA - Ethylene Vinyl Acetate - is a thermoplastic polymer used in solar modules as an encapsulating agent, as when heat is applied to the assembly, it forms an insulating and sealing film around the solar cells. It prevents the entry of air and the formation of humidity, lets the sun's energy through while being resistant to degradation of sunlight over time.

On bifacial solar panels, the backsheet is made of glass to allow the absorption of light reflected on the ground. This can represent gains of more than 15% on highly reflective substrates such as sand.

The problem with cheap solar glass

Cheap solar glass can cloud over time which will greatly reduce the solar panel’s efficiency. Apart from being a glass that is easier to break, even if the glass only microcracks, it will allow water to penetrate and create a fire hazard. This is general safety issue, that can damage not only the photovoltaic system but also the building, if installed on a rooftop.

To avoid this type of problems, look for a solar panel that has IEC certification. This means that the solar panel glass of that panel has withstood the quality and safety tests successfully.