R. Dr. Francisco Sá Carneiro

Zona Industrial de Bouro - Letra C

4740-010 Esposende, Portugal

Revolutionizing PV Plant Efficiency: Chemitek Introduces Antistatic Solar Armor (ASA)

A Breakthrough Coating Redefining Soiling Mitigation Strategies

The global issue of soiling on photovoltaic (PV) plants has emerged as a major challenge, significantly impacting energy output and resulting in estimated global losses of 3% to 5%, translating to a substantial 3 to 5 billion euros. Particularly in arid and semi-arid regions, soiling exerts a significant toll on PV plants, innovative strategies are needed to mitigate its effects.

The impact of soiling on Solar Panels

Reduction in Energy Output

- Dirt and soiling on the surface of solar panels act as a barrier, obstructing sunlight from reaching the photovoltaic cells.

- Reduced sunlight absorption translates to lower energy conversion efficiency, leading to a reduction in overall energy output.

Financial Implications

- Energy losses due to soiling will lead to reduced revenues and longer payback periods for solar investments.

Operational Costs

- Soiling, especially soil banding, can lead to the creation of hotspots that will reduce the lifetime, or even require the replacement of the panels, and therefore increase the costs to keep the plant running.

- Frequent cleaning becomes a necessity to maintain optimal solar panel performance, leading to increased operational costs.

- Manual cleaning processes involve labor, water, and sometimes the cleaning solutions, all contributing to the overall cost of solar plant maintenance.

To combat this challenge, companies often resort to more frequent cleaning schedules, deploying soiling measurement equipment, and investing in anti-soiling coatings (ASCs).

Anti-Soiling Coatings (ASCs)

Anti-soiling coatings (ASCs) are specifically designed to mitigate the impact of dirt and soiling on solar panels. These coatings aim to:

- Prevent Dirt Accumulation: ASCs form a protective layer on the surface of solar panels, making it more difficult for dirt, dust, and other contaminants to adhere to the panels.

- Maintain Energy Output: By reducing the accumulation of dirt, ASCs help maintain optimal sunlight absorption, ensuring higher energy output from the solar panels.

While ASCs represent a promising technology, their delayed integration into the solar industry mainstream begs the question: Why haven't ASCs attained standard status yet?

The challenges hindering the proliferation of ASC technology include:

- Application Method: Retrofitting ASCs onto existing solar panels can be a complex process. The surface must be flawlessly clean before application, requiring specialized tools and manual labor.

- Application Cost: The cost of applying ASCs, including labor and equipment, can sometimes outweigh the cost of the coating itself. This presents a challenge in achieving a cost-effective solution.

- Coating Cost: The cost of the coating per square meter varies based on factors such as the manufacturer, technology, and expected lifetime. Balancing cost-effectiveness with performance is a critical consideration.

- Real-World Performance: Simulating real-world conditions in a laboratory, to test or certify ASCs, is challenging due to the multitude of variables involved. This can lead to uncertainties in predicting actual energy output gains and coating lifespan.

- Longevity and Maintenance: The longevity of ASCs under varying environmental conditions is a concern. Harsh weather, abrasion, and exposure to pollutants can impact the coating's effectiveness over time, requiring periodic reapplication.

Retrofitting ASCs onto existing plants involves a multistep process, demanding specialized tools, manual labor, optimal accessibility, and specific weather conditions, often making the application process more expensive than the coating itself.

In response to these challenges, Chemitek Solar introduces the Antistatic Solar Armor (ASA), a revolutionary antistatic and antiadherent coating for PV modules.

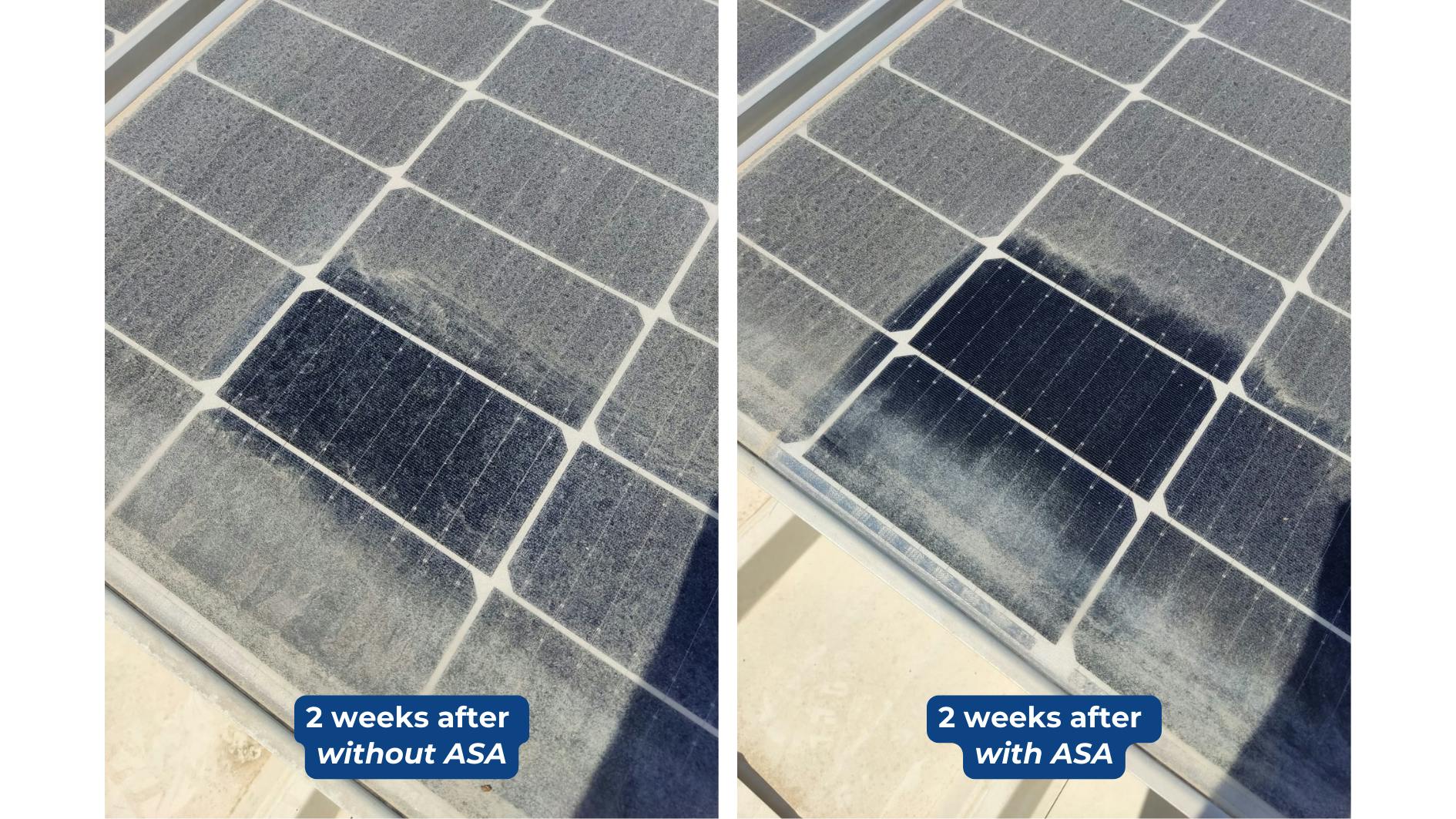

ASA is designed to be easily applied, adaptable to diverse weather conditions, and to excel in dry and moderate climates. Notably, it sustains module cleanliness between cleanings, unlocking an additional energy output of up to 5%.

Environmentally conscious, ASA is readily biodegradable, pH neutral, and poses no threat to PV modules, the environment, or the workforce employing it. ASA sets a benchmark as the soiling mitigation coating with the simplest application in the market, seamlessly integrating into standard PV plant cleaning operations without necessitating additional steps.

Coating adhesion to the module surface is facilitated by the mechanical action of brushes against the glass, eliminating the need for prior cleaning. With virtually zero application costs, the coating itself incurs only a minimal cost per square meter, ensuring high competitiveness.

ASA boasts a six-month lifespan under typical soiling conditions, allowing for reapplication directly over the existing layer without removal. Its antiadherent properties prove beneficial for PV plants soiled with contaminants like cement dust, stone dust, metal oxides, and others, delaying adhesion and enhancing cleaning efficiency, thereby reducing soiling losses.

TÜV Sud has rigorously tested ASA, affirming its safety for all module components, including the Anti-Reflective Coating (ARC). Importantly, ASA application atop the ARC does not compromise its performance, as validated by TÜV Sud tests.

In addition to ASA, Chemitek Solar introduces a variant of the antistatic coating tailored for manual cleanings, incorporating cleaning agents: the Solar Wash Protect.

Criticalities:

ASA necessitates plant cleaning with water and equipment featuring brushes (e.g., robot or tractor brush), potentially limiting its use in desert regions with limited water access.

In conclusion, the issue of soiling on solar panels is a substantial challenge with implications for energy production and financial viability. While anti-soiling coatings hold promise in addressing this problem, the challenges associated with their application, cost, and real-world performance underscore the complexity of finding effective and economically viable solutions in the solar industry.

However, the solution developed by Chemitek Solar represents an innovative solution to the persistent challenge of soiling in photovoltaic installations. By providing a cost-effective, environmentally friendly, and easily applicable coating, ASA is set to revolutionize the solar industry's approach to soiling mitigation.