R. Dr. Francisco Sá Carneiro

Zona Industrial de Bouro - Letra C

4740-010 Esposende, Portugal

Hotspot Effect

Obtained through the sun, solar energy has grown tremendously in recent years, it is already one of the most important natural renewable energy sources, and its potential is almost limitless.

Very briefly, photovoltaic systems need sunlight to produce energy and consist of several photovoltaic cells connected in series (strings) and in parallel. However as simple as it may seem to work, solar panels can lose efficiency due to several factors being one of the most frequencies the appearance of hotspots.

The hotspot effect is considered to be one of the most common causes of solar panel failure or fire risk. This problem is quite serious as it will affect not only the production, but as well the safety of a photovoltaic plant.

Causes for the appearance of hotspots

There are several reasons that lead to the appearance of hotspots on solar panels:

- Projected shadows - the shadows can appear on the panels by an object close to or above the panel e.g. trees, equipment, buildings, walls, etc.

- Soiling - one of the main causes of this problem is soiling. Dirt and deposits on the glass surface of the panel will prevent light from entering the cell at that particular point and will block it.

- Structural damage - can result from production and quality problems, such as defective cell arrangement, lamination problems or poor welding, as well as from handling of the panels in the installation

What are hotspots?

Hotspots, exactly as the name implies, are localized temperature increases. If one of the connections between photovoltaic cells presents a problem of increased resistance and a consequent increase in the potential difference, the entire string of cells is affected.

The fact that the current is close to the short circuit current can lead, as a result of the increase in temperature at the limit, to a self-inflammation of the solar panel.

Therefore, hotspots are areas of high temperature that affect a solar cell by consuming energy rather than generating it, significantly affecting the efficiency of the solar panel during power generation.

The hotspot effect occurs when a solar panel is shaded and the current cannot flow around weak cells. Eventually, the current will concentrate in some cells, causing them to overheat and potentially melt. The panels are made of semiconductor material that produces energy when photons hit the surface and activate electrons. If the operating current of the overall series approaches the short-circuit current of the "bad" cell, the overall current is limited by the bad cell. The extra current produced by the good cells then drives the good solar cells. If the series string is short-circuited, the direct bias on all these cells inversely biases the shaded cell. Hotspot heating occurs when a large number of cells connected in series causes a large reverse polarization in the shaded cell, leading to a large power dissipation in the poor cell. Essentially, all the generating capacity of all the good cells is dissipated in the poor cell by overheating it.

If a cell or group of cells in a solar panel cannot receive light, they will not be able to produce energy. Since solar cells are connected in series, one weak cell or group of cells will affect the energy production of all the cells in the same string. This problem reduces overall output efficiency while it will accelerate material degradation. Hot spots are rarely stable and usually intensify until the panel completely fails in terms of electrical output and/or insulation.

Consequences of hotspots

One of the big problems with hot spots is that if they are not caught in time, they have a very significant impact on the neighboring cells as well as the whole module, affecting the total power generation, leading in extreme cases to the collapse of the panels.

Hot spots cause excess energy and overheating in a small area this can lead to cracking of the cell, melting of the solder, or degradation of the entire solar cell. Hot spots often also cause the protective glass to crack and can lead to moisture ingress leading to system failure.

How can I know if my plant has hotspots?

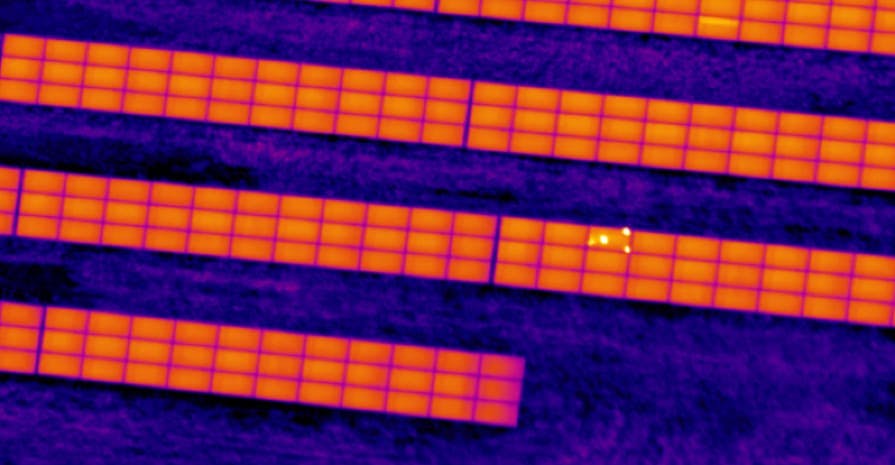

The easiest and most efficient way to see if there is a hot spot is to monitor the temperature of the surface of each module using, for example, thermography. By using this technique, you will have access to thermographic images of your modules, which show the temperature distribution across the different modules, and you can see whether or not there are heat points.

How can I avoid them?

This problem is often not visible to the naked eye, unless there is a very clear color difference, such as a brownish spot in the solar module.

When hotspots are already present on solar modules, there is not much that can be done. Due to the nature of this problem, the cells will damage and degrade leading to the rupture of the module, as such the solution often involves the purchase of a new module, however, there are several measures that can be taken to prevent and avoid hotspots.

- Invest in quality - Make sure you buy a system from a specialized and certified company that is a reference in the market. Furthermore, the service provided by this type of company is much broader and more specialized. The panel material must be of good quality in order to have optimal thermal properties. Read the manufacturers' instructions for the solar modules you have purchased. It is highly recommended to read the manufacturers' recommendations, as they will usually include information about the product in order to make it work as well as possible.

- Maintain good airflow - Hotspots are a result of heat buildup in the cell, by having low airflow in the system this will increase the chances of creating hotspots. A good solar panel system will always ensure adequate ventilation and airflow to prevent the panels from overheating.

- Use a solar tracking system - solar tracking systems make the panels move according to the direction of the sun, unlike normal systems where the panels are always in the same position. Since these systems always expose the panel to direct sunlight, it ends up reducing hotspots. Of course, there is a downside to this system: the price. The solar tracking system is expensive and will increase the cost of electricity production due to the additional moving parts that are required in this type of equipment.

- Install the panels at the right angle - Look at the surroundings of the place where you are going to install the panels and the solar exposure and understand the best angle for their placement. It is very important to install photovoltaic panels without obstructions. This means that they should not be too close to buildings or trees or other possible "problems" that will create shade. It is important to consider, together with a specialized team of installers, the best way to place your panels.

- Most importantly, panel cleaning and maintenance - One of the main reasons for hotspots is dirt accumulated on the panel. A dirty module, with soil accumulated on the bottom of the panel, bird droppings, leaves, water stains, among other contaminants, will block the sunlight from passing through the solar glass and into the cell, generating heat spots. Regular cleaning of your panels will ensure that this problem does not arise, reducing the effect.

Read more about the causes and effects of this problem in the article in PV magazine Hot spots: Causes and effects

Cleaning Solutions by ChemiTek

To avoid the accumulation of soiling, one of the main causes for the appearance of hot spots, you should optimize the cleaning of your panels. Preventive maintenance of your photovoltaic panels is very important, as well as the use of effective cleaning solutions and coatings in order to avoid the reappearance of soiling and leave your solar panels clean and working at full efficiency.

Also, it is important to have in mind that the solutions used need to be specific for solar panel cleaning to avoid voiding the warranty of the solar modules. These products need to be safe for all the different components of the solar modules: aluminium frame, silicone seal, glass and ARC (anti-reflective coating).

With Chemitek certified solutions for the solar industry, soiling will not stick to the solar module glass, keeping the solar glass cleaner between cleanings and increasing the performance of the next cleaning and the energy efficiency of your solar installation. Avoid hotspots by protecting your modules with the right coating for the local climate and environmental conditions of the location of your PV modules. Learn more about hydrophobic and antistatic coatings in our article.

Do you have any suggestions or topics about the solar industry you would like to read here? Reach us by email!