R. Dr. Francisco Sá Carneiro

Zona Industrial de Bouro, Letra C

4740-010 Esposende, Portugal

What type of water can I use to clean the solar panels?

Solar modules need to be cleaned to avoid the loss of efficiency or even possible damages. Your location, the local climate, the type of soiling and the cleaning method will influence the frequency of cleaning. Unknowingly, many homeowners clean their solar installations in a simpler way, namely with tap water and a mop or brush. However, it must be kept in mind that the glass of the solar modules requires specific care. The glass is tempered and coated with an anti-reflective coating, commonly known as ARC (anti-reflective coating) and if not cleaned properly irreversible damage can be caused to both. Incorrect cleaning may even void the warranty of the modules. Before cleaning check the manufacturer's guidelines to avoid surprises.

Before cleaning confirm manufacturer's guidelines. The majority of module manufacturers allow cleaning with soft water and soft bristles’ brushes. The use of detergents is more limited, and they must be at least pH neutral and free of aggressive chemicals. When in doubt choose a detergent certified specifically for solar modules such as ChemiTek's Solar Wash Protect.

Types of water

Studies show that tap water is almost always unsuitable for cleaning solar modules. The presence of minerals will, after drying, form limescale/stain deposits on your panel glass. This will decrease energy production or even damage the panel due to the creation of hotspots. Therefore, one of the most important things to consider when cleaning your panel, apart from the product you will use to remove the dirt, is the type of water used.

Hard water: Hard waters are those with a high concentration of salts and minerals, mainly cations of calcium and magnesium, or cations of other metals, such as barium, iron, manganese, strontium and zinc. The hardness of water can differ geographically, i.e. it will depend on the geological nature of the place the water passes through and with which it comes into contact. Hard water is associated with areas where the rocks are of a calcareous nature. Waters from limestone areas are harder than waters from granitic areas (waters from granitic areas are typically soft).

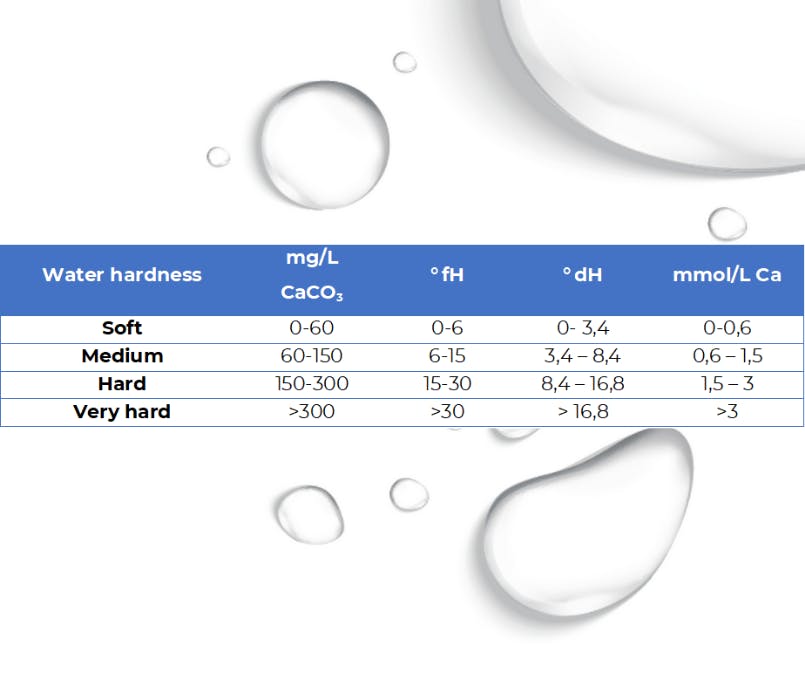

Water hardness classification:

Water with organic material: Organic material is all material of plant or animal origin produced in the aquatic environment itself or introduced into it through dumping or rainwater runoff. Organic material suffers a process of decomposition, which results in the release of nutrients into the environment that will be used by algae and higher plants for their growth.

Recommended waters for cleaning solar panels The type of water used in the cleaning and maintenance of solar panels is one of the fundamental steps for correct cleaning. The use of hard water or water with a high content of organic matter (such as water from rivers and lakes) is not recommended for cleaning solar panels. It is recommended to use water with the least possible amount of impurities (the least possible amount of minerals and organic matter), with a neutral pH, non-abrasive to the panel materials.

The best water for cleaning is demineralised water obtained through reverse osmosis, as this process eliminates most impurities. Distilled or deionised water, free of mineral ions and other impurities, are also a good option for cleaning panels.

- Water obtained by reverse osmosis: The osmosis process consists of the movement of water through a semi-permeable membrane, driven by the difference in concentration of contaminants. In normal osmosis there is an outflow of water from the less concentrated medium to the more concentrated medium through the membrane. In reverse osmosis the opposite happens, i.e. water passes from the more concentrated solution (hard water or water with impurities) to the less concentrated solution, and the membrane will retain mineral salts and impurities. In reverse osmosis, the water flow is driven by mechanical forces, such as pressure pumps, resulting in high purity water. The downside of reverse osmosis is that 20% to 50% of the water is rejected during the process. The harder the water, the higher the percentage of rejected water.

- Distilled water: Distilled water is obtained by the distillation process (evaporation followed by condensation of the water). Most impurities in water can be removed through this process, namely impurities whose boiling temperature is higher than the boiling temperature of water (soluble minerals such as calcium, and other heavy metals such as mercury and arsenic are removed). However, it should be considered that certain volatile organic compounds with boiling temperatures lower than those of water may evaporate together with water and remain in the final purified water. For this very reason, we cannot say that distilled water is totally free of impurities.

- Deionised water: This is water from which ions (the constituents of salts such as calcium and magnesium) have been removed. The most common process for obtaining them is the use of ionic resins that capture these ions from solutions. Again, this method of water treatment may not be able to remove any impurities, such as certain organic compounds. Distilled water can sometimes be purer than deionised water (it can eliminate more impurities due to the difference in boiling points). The lifetime of the resin will depend on the hardness of the water used. The harder the water the shorter the life of the resin. The deionisation process is often the step prior to reverse osmosis to decrease the amount of water rejected and increase the lifetime of the membrane.

In addition to the use of physical processes to obtain soft water there is also the possibility of using a softening agent that will make the water softer. This agent will remove the ions making the water softer and thus preventing the appearance of stains and scaling.

The advantage of this solution is that there is no need for the initial investment in filtration equipment and consumables and it is scalable. Filtration systems are limited to their rated capacity and if more water is required, the system will not keep up. So, this solution is widely used by cleaning teams both in homes and large plants.

With this problem in mind ChemiTek has developed Water Softening Agent, a softening agent specifically for use in the solar industry. Biodegradable, highly concentrated and with no influence on the pH of the water, it is a very low cost per m2 solution that avoids large investments and is completely scalable.

Did you use the correct water and a certified detergent and still didn't get perfect results? We then suggest the use of a contaminant removal agent specific to your problem that is proven not to damage the solar modules, as well as the subsequent use of suitable antistatic or hydrophobic coating to prevent the reappearance of dirt. You can know more about ChemiTek's solutions here.